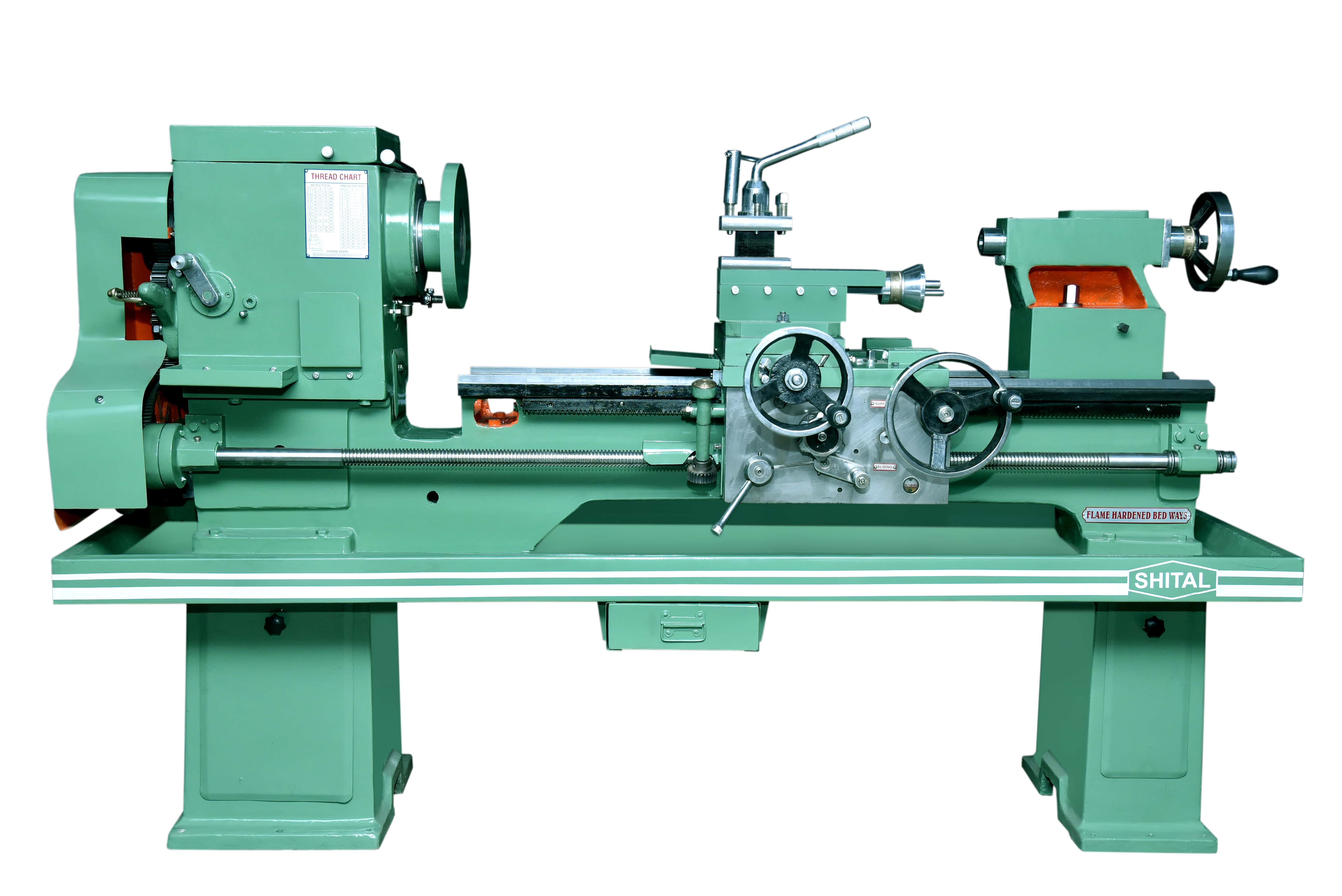

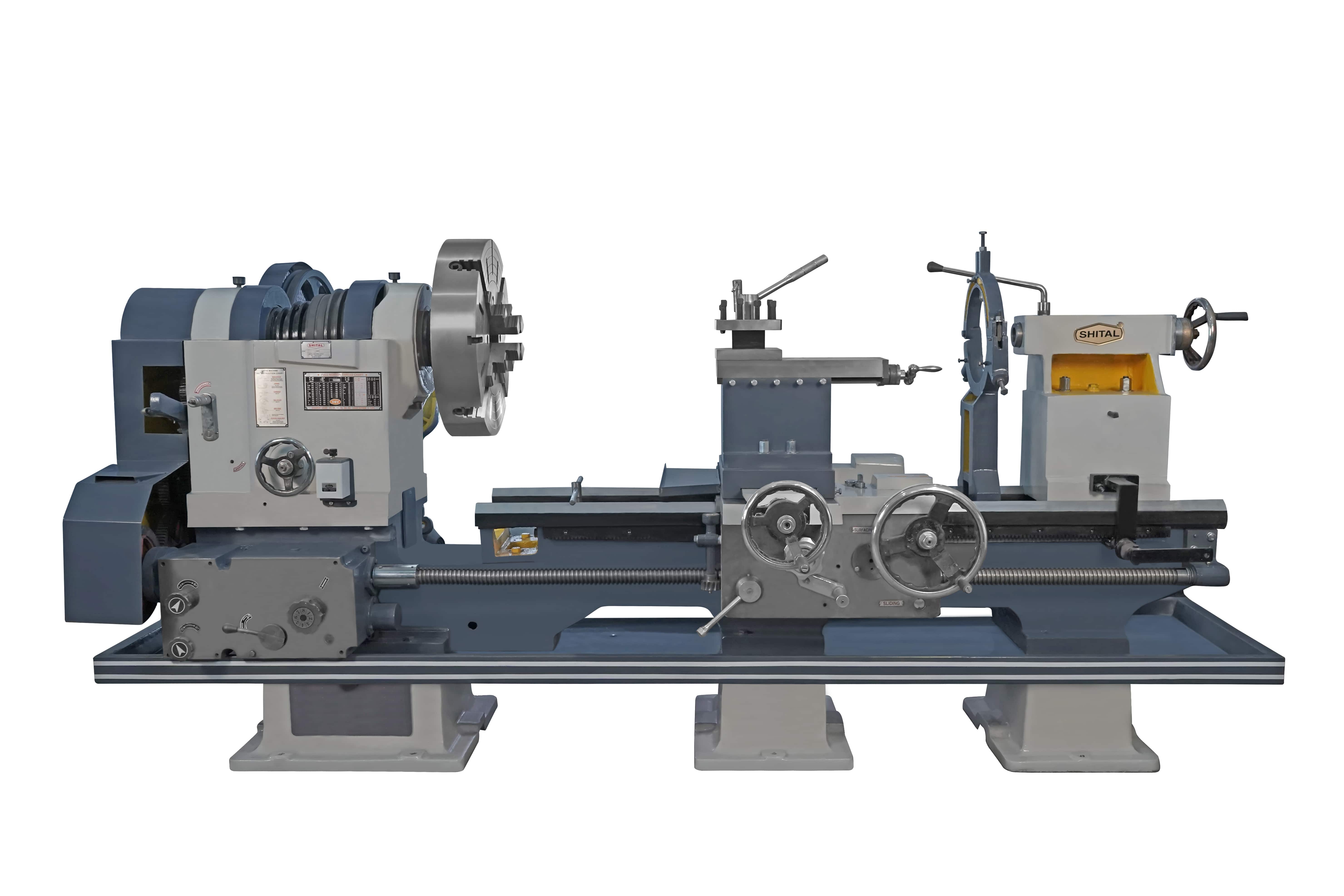

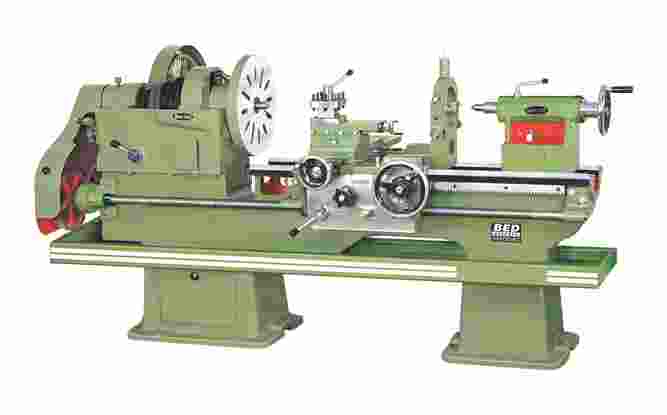

Being a customer oriented firm, we are engaged in lathe machine manufacturer in Rajkot and India. We have wide range of Heavy Duty Lathe Machines, All Geared Lathe Machine, and Lathe Machine Accessories. Shital Machines has been engaged in Machine Tools manufacturing since 1983. We are manufacturing various kind of Precision Lathe Machines like Heavy Duty & Extra Heavy Duty Belt Driven, Heavy Duty All Geared, Medium Duty Belt Driven Lathe Machines.

What is Lathe Machine & Why it is used For?

The main function of a lathe machine is to give various material pieces the appropriate forms using a variety of operations, such as cutting, turning, sanding and grooving, knurling, etc. Shital Machine Tools the leading lathe machine supplier in Rajkot & India, offers various lathe machines that can be used to do multiple operations and spin a component on its axis using a machine dock.

The all-geared lathe machine in India is used in building sites to generate high pressure, as standard lathes don't seem to function well enough there. The depth, feed of the machine, and intended speed are only a few of the numerous parameters that must be met for each operation on the lathe Machine by Shital Machine tools to be completed precisely. Our Machines are designed to maximise efficiency and yield the finest possible results. Selecting the best Lathe Machine Suppliers in Rajkot guarantees financial savings in addition to time and effort savings.

Working Principle of Lathe Machine

- Construction: The main components of the lathe are the carriage, headstock, tailstock, quick-changing gearbox, and bed.

- Bed: The bed is a solid, durable casting that holds the lathe's operating components. In addition to carrying the tool, the headstock and tailstock retain the material and act as a platform for movement.

- Headstock: The headstock is fastened to the right side of the left bed and houses the driving pulleys, rear wheels, headstock spindle, live centre, and feed reverse gear. The cylindrical headstock spindle is a shaft that joins the tools used to hold the work and the motor's output.

- The gearbox: A quick-change gearbox with a range of sizes of gears is located beneath the headstock.

- Legs: The device's legs sustain the weight of the entire machine and are firmly fixed to the ground by foundation bolts.

- Carriage: The carriage, which is located between the headstock and tailstock, supports, guides, and feeds the tool against the workpiece as it is being operated. The main parts of the carriage are:

- The H-shaped saddle casting is placed above the lathe shaft. It is compatible with the cross slide, complex rest, and tool post.

- The cross slide provides the cutting tool with a mounted or motorised cross movement. It is fastened to the top of the saddle.

- The compound rest, which is fastened to the top of the cross slide, supports the tool base and the cutting tool.

- The tool post is fixed and firmly clamps the cutting tool or tool holder at the proper height around the work centre line resting on the compound.

- The apron, which is fastened to the saddle, contains the gears, clutches, and levers required to move the carriage or cross slide.

- The tailstock: The tailstock is a moveable casting located on the bottom of the bed, right across from the headstock. By moving the tailstock down the bed, it is possible to handle varying workpiece lengths between the centres. You may lock the tailstock in any desired position with the tailstock clamp. The tailstock spindle has an internal taper to hold the dead centre and tools with tapered shanks, such as drills and reamers.

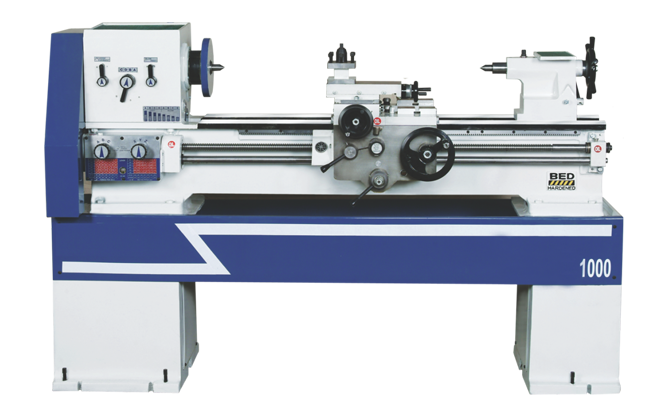

Types of Lathe Machine

- CNC Lathe Machines - When it comes to lathe machine in Rajkot, computer numerical control, or CNC, provides exceptional accuracy quickly. The same components found in manual lathes—the spindle, headstock, tailstock, tool turret, chuck, and centres—are used in their construction. CNC lathes are the most popular lathe machines because of their higher productivity and accuracy. These are pretty advanced models of lathes. CNC lathes use computer programming to operate their equipment.

- Engine Lathes Machines - Among other operations, engine lathes can perform turning, facing, threading, knurling, and grooving. An engine lathe machine's bed, saddle, headstocks, and tailstocks are only a few of its parts. While the headstock of engine lathe machines is stationary, the adjustable tailstocks are used for knurling operations.

- Turret Lathe Machines - Turret lathes are sometimes known as capstan lathe machines. These machines are used to produce duplicate parts in large quantities. Turret lathes are capable of facing, turning, reaming, and boring, among other operations. Instead of the tailstock, they have a saddle-mounted hexagonal turret. Time can be saved, and mistakes can be decreased by using one machine for many activities. The fundamental advantage of using turret lathes for large projects is that even inexperienced people can operate them.

- Speed Lathe Machines - The speed lathe is typically used for metal polishing, spinning, and woodturning. They are constructed using high-speed spindles, which are used to manufacture various furniture parts, bowls, and baseball bats. Speed lathe machines have a speed range of 1200 to 3600 rotations per minute.

- Automated Lathe Machines - These lathe machines accomplish work automatically. Compared to automatic lathe machines, ordinary lathes have a major shortcoming; hence, they cannot be used for big production. Using an automatic lathe has several advantages, chief among them being the ability for one person to operate four or five machines at once. Automated lathes are both powerful and fast machinery.

- Tool Room Lathe Machines - Tool room lathes are utilised when extreme precision is needed. Turning, grinding, drilling, boring, and reaming are all done on the tool room lathes. The gearbox can change speed from low to high because of its connection to the headstock. They operate in a strictly regulated atmosphere at up to 2500 rpm.

- Special Purpose Lathe Machines - A wide range of activities that would be impossible to complete on regular or other lathes can be completed using special-purpose lathes. The best application for special-purpose lathe machines is the mass production of comparable components. Vertical lathes, wheel lathes, t-lathes, tracer, multi-spindle lathes, production lathes, duplicate lathes, etc., are examples of special-purpose lathe machine types. Wheel lathes are used for the machining of rail rods and journals. They are also employed in the rotation of the threads on locomotive wheels. T-lathes are used for the machining of jet engine rotors.

Uses of Lathe Machine in India

- Forming - The process of forming involves utilising a specific machine with the reverse profile of the required component on its cutting edge to create a shape on a lathe. Form tools are used to convert complicated profiles through plunge feeding. Forming tools come in two shapes: round and flat. Chattering and a poor finish are the results of long-form machine profiles. Cuts have to be done very carefully. In general, complex form tools are costly and challenging to manufacture. A single point can produce complex profiles more efficiently than by forming.

- Contour Turning - The optimum contour turning technique is used when manufacturing complex things, such as turbine blades. First, a design of the right shape is manually added to plaster, plastic, or any other soft substance. Theoretically, only mechanical devices like mechanical linkage, spring-loaded cam supports, double-track cams, and lever arms can provide the proper shape. Still, in actual use for large quantities, they are inefficient.

- Ultra Precision Machining - Ultra-precise machining finds applications in computer skills, electronics, nuclear, and defence manufacturing of precision parts. Diamond wear can be minimised by using cryogenic diamond turning, which involves chilling the tool system using liquid nitrogen to a temperature of -120A C. High levels of precision, stiff work-holding devices, and incredibly quick spindle speeds are features of the machine tools made for these uses. Dimensionally stable building elements with minimal thermal expansion are used to build these devices.

- Hard Turning - Hard machining is the process of machining steel with a hardness of 45 HRC or greater. The heat generated by the rough machining process is used to plasticise or anneal the material at the cutting point. The fast speed of the chips transfers the heat away from the weld point. The tool merely skids across the work area during hard machining. For hard turning, the range of cutting speeds for ceramic and CBN tools is 120 to 180 m/min. Finishing is one kind of hard turning. The allowance for hard turning is almost twice that of the allowance for grinding. A rough cut of up to 0.4 mm may provide a completed cut of nearly one-third of it. The feed rate could be as low as 0.1 mm/rev.

- Cams Machining - Cams are often manufactured using a 212-axis NC machining centre. The tool path is generated using either the mathematical curves in the cam profile or the follower's motion equation. Two-and-a-half-axis machining centres can be used for paraxial, linear, and circular form machining. The application takes the cutter diameter into account while determining the cutter location data.

Contact us

Shital Machine Tools offers high-quality engineering workshop equipment. Since the beginning, Shital has led the way in machine tool technology, offering a distinctive array of intelligent precision engineering technologies and solutions for a wide range of industrial applications. Shital Machine Tools offers the best quality lathe machines as they are the leading Lathe machine manufacturer in Rajkot & India.

As a leading global industrial tools and gear provider, we ship our goods worldwide. To be successful and meet expectations, Shital Machine Tools promises to develop methods and designs that make business operations more convenient than before. Get in touch with us to find out more about the machines and to obtain premium tools.

FAQ's (Frequently Asked questions)

The average cost of different kinds of Lathe Machine are listed below:

- Medium Duty Lathe – 2,09,000

- Light Duty Lathe- 1,39,000 to 1,85,000

- Extra Heavy Duty Lathe- 9,50,000 to 19,50,000

- Heavy Duty Lathe- 3,45,000 to 6,25,000

- High-speed All-Geared Lathe to 6,70,000

- Heavy Duty Mini Lathe - 98,000

Numerous industries use lathes, including aerospace, automotive, construction, farming, fluid power, energy, oil, food, and medicine.

Throughout the projected period, the lathe machine in Rajkots market in India is anticipated to rise at a CAGR of about 7%. The market for lathe machines is expanding due to two main factors: the increased use of CNC lathe machines and the growing demand from end-use sectors like automotive and aerospace & defence.

A lathe is a tool that uses tools applied to the workpiece to create an item with symmetry about an axis of rotation. It can be used to conduct various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning.

The engine lathe is the most popular type among all the manual lathes used in machine shops. Turning, end face, grooving, knurling, and threading are among the processes that the engine or centre lathe can complete.

Lathe machine in Rajkot and all other machinery will see many improvements and excellent things in the future. This encompasses technologies such as automation, 3D printing, next-generation CNC, virtual reality, advances in CNC programming, and CNC intelligence.